Understanding Packaged HVAC Systems

Packaged HVAC systems are engineered to offer heating, cooling, and air conditioning through a single unit installed outside the home or commercial building. These systems are distinct from split systems, which separate components between indoor and outdoor locations.

Components of Packaged HVAC Systems

A packaged HVAC system combines several components into one outdoor unit, streamlining installation and maintenance. These components typically include:

- Air Conditioner/Heat Pump: Provides cooling and, for heat pumps, reversible heating.

- Evaporator and Condenser Coils: Enable the heat exchange process.

- Compressor: Circulates the refrigerant and is key for the cooling cycle.

- Blower/Fan: Moves air through the system.

- Thermostat Connection: Manages the system based on user settings.

Types of Packaged Systems

Different configurations of packaged systems address various heating and cooling needs:

- Packaged Air Conditioners: Offer cooling and sometimes electric heating using resistance heaters.

- Packaged Heat Pumps: Provide heating and cooling by reversing the refrigeration cycle.

- Gas/Electric Packaged Units: Combine an air conditioner with a gas-powered furnace.

- Packaged Dual-Fuel Systems: Usually a heat pump and a gas furnace, switching between modes for efficiency.

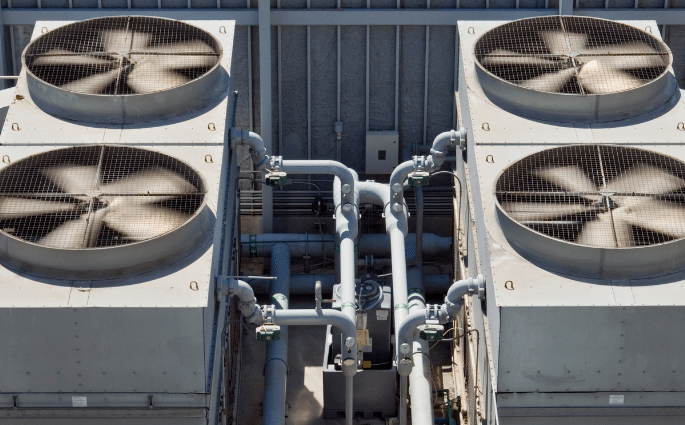

Packaged units are commonly found on rooftops or at ground level and are favored for their all-in-one system convenience, especially where space is limited.

Installation and Integration

When we consider the installation and integration of packaged HVAC systems, attention to detail is crucial in the setup to ensure optimal performance and longevity. This part will cover critical aspects such as space planning, ductwork configurations, and adherence to professional standards during installation.

Space Considerations and Placement

Determining the appropriate space and placement for both indoor and outdoor units is foundational for a successful packaged HVAC system installation. For residential applications, space-saving design is often a priority. The outdoor unit requires a solid, level foundation, usually a concrete pad, and must be positioned away from obstructions with ample clearance for air intake and exhaust. The indoor unit placement should consider ease of access for maintenance and repair, with adequate space for air circulation to ensure efficient operation.

Residential Placement Checklist

- Level foundation for the outdoor unit

- Clearance from obstructions

- Accessible location for the indoor unit

- Ample space for maintenance activities

Commercial Spaces Considerations

- Load bearing requirements for roof placement

- Vibration isolation to reduce structural noise

- Security measures to prevent unauthorized access

Ductwork and Ventilation Setup

Effective ductwork and ventilation setup is imperative for efficient airflow and indoor air quality. We must design ducts to deliver air evenly throughout the installation space, minimizing leakages and optimizing pressure balance. Ducting materials should be chosen based on durability and the specific needs of the HVAC system, such as insulated ducts to prevent thermal loss. Proper ventilation is essential to remove indoor pollutants and ensure a constant supply of fresh air.

Key Aspects of Ducting

- Ensure sealed joints and minimal leakage

- Balance airflow for even temperature distribution

- Use insulated ducting where necessary to minimize energy loss

Professional Installation Best Practices

Enlisting a certified HVAC professional for installation guarantees that the system complies with regional codes and manufacturer’s specifications. Professionals will also assess the right system size for the space to avoid inefficiency. They use precise tools and techniques for handling refrigerants, wiring, and system diagnostics. For both residential and commercial applications, a professionally installed HVAC system can mean the difference between a reliable, efficient setup and one fraught with problems.

Checklist for Professional Installation

- License and certification verification

- Compliance with local codes and standards

- Accurate sizing and load calculations

- Thorough system testing post-installation

Performance and Energy Efficiency

In this section, we will explore the importance of energy efficiency ratings and the benefits that high-efficiency HVAC units bring.

Energy Efficiency Ratings

When examining packaged HVAC systems, it’s crucial to understand two primary energy efficiency metrics: SEER (Seasonal Energy Efficiency Ratio) and EER (Energy Efficiency Ratio).

SEER

Measures the cooling output during a typical cooling-season divided by the total electric energy input during the same period. The higher the SEER rating, the more energy-efficient the unit is. For instance:

| SEER Rating | Efficiency Level |

| 13-15 | Standard |

| 16-20 | High |

| 21+ | Very High |

EER

Reflects the energy efficiency of the system at peak operating times. Just like SEER, a higher EER indicates greater efficiency.

Note: It’s valuable to compare these ratings when selecting a packaged HVAC unit to ensure optimal energy efficiency and cost savings.

Advantages of High-Efficiency Units

Packaged HVAC systems with high energy efficiency not only provide substantial cost savings on utility bills but also have a lesser environmental impact.

- Cost Savings: By choosing a unit with a high SEER and EER rating, we can lower our energy consumption, which translates to lower utility bills over the lifespan of the unit.

- Environmental Impact: Energy-efficient systems require less energy, leading to reduced greenhouse gas emissions and a smaller carbon footprint.

By prioritizing energy efficiency in HVAC systems, we contribute to a healthier environment while also enjoying monetary benefits.

Maintenance and Longevity

Proper maintenance ensures the efficient operation and longevity of packaged HVAC systems. We’ll discuss the required routine tasks and address common repair issues with their solutions.

Routine Maintenance Tasks

It’s vital for us to conduct several maintenance tasks regularly to keep our packaged HVAC system running smoothly. Here are key tasks and how often they should be performed:

Monthly

- Check and replace air filters: Dirty filters restrict airflow, causing the system to work harder than necessary.

Seasonally

- Inspect and clean coils: Both the evaporator and condenser coils should be free of debris and dirt to maintain efficiency.

- Verify refrigerant levels: Proper levels are crucial for effective cooling and heating.

Annually

- Professional evaluation: Let a technician examine the compressor, coils, and all connections for any potential issues.

Common Repair Issues and Solutions

Throughout the lifespan of a packaged HVAC system, certain components tend to require attention. We’ll outline these and suggest practical solutions:

- Compressor problems: Detectable through unusual noise or system malfunction. Solution often involves professional repair or replacement.

- Evaporator coil freezing: Signs include reduced cooling capacity and visible ice on the coil. Thawing the coil and ensuring unrestricted airflow are immediate steps, but we need to verify refrigerant levels and check for any leaks.

- Condenser coil issues: Poor heat exchange can be due to a dirty condenser coil. Cleaning it restores function. If damage is extensive, coil replacement may be necessary.

Regular maintenance and prompt repair of issues are key to the longevity and efficiency of your HVAC system. Our adherence to these guidelines will result in reliable performance and reduced energy costs.

Considerations for Homeowners and Businesses

When considering a packaged HVAC system, we must assess initial investment, long-term cost-effectiveness, the unit’s sound level, and air quality management features.

Budget and Cost Considerations

Budgeting – The upfront cost of packaged HVAC systems varies. Packaged air conditioners are typically a cost-effective choice for cooling, while packaged heat pumps offer both heating and cooling solutions, potentially saving money in temperate climates. A packaged dual fuel system, although initially more expensive, can be more cost-efficient for those who experience extreme weather fluctuations, as it combines a heat pump with a gas furnace to optimize energy use.

Long-Term Savings – Installing heat strips in milder climates can be more economical, while selecting a high-efficiency furnace or blower motor will result in long-term savings for homeowners and businesses alike. Although a gas furnace may be costlier upfront, its longer lifespan and lower operational costs can make it a wise investment.

Noise Levels and System Quietness

Blower Motors – Systems with variable-speed blower motors are generally quieter and more adaptable to varying conditions, providing a more consistent airflow and reducing sound levels.

Installation Location – We should also consider the location of the unit. An outdoor installation for a packaged system may be preferable to minimize indoor noise.

Air Quality and Additional Features

Air Purifiers and Humidifiers – For those concerned with indoor air quality, additional features like air purifiers and humidifiers are beneficial. These can be integrated into many packaged HVAC systems.

Filtration – Enhanced filtration options available in packaged units can capture more contaminants, removing them from circulated air to improve overall air quality.

By carefully evaluating these considerations, we can ensure that the packaged HVAC system we choose aligns with our specific needs for comfort, cost, and air quality.

Frequently Asked Questions

What are the typical installation configurations for packaged HVAC units?

Packaged HVAC units typically come in two main configurations: horizontal and downflow. Horizontal units are ideal for installation on the side of a residence, often at ground level or on the roof. Downflow units are designed to be placed on the roof, discharging air downward into the ductwork that runs throughout the building.

How many electrical connections are generally required during the installation of a HVAC package unit?

Generally, a single electrical connection is required for a packaged HVAC unit. This powers the entire system, which includes the compressor, fan motors, and any additional components such as electric heaters. Professional installation ensures this connection meets local codes and power requirements.

What variety of ventilation options are available in packaged HVAC systems?

Packaged HVAC systems offer several ventilation options such as economizers for fresh air intake, power exhaust to regulate building pressure, and demand control ventilation for air quality management. These options aid in customized airflow patterns suitable for the building’s requirements.

Can you explain the concept and benefits of a dual-fuel heat pump?

A dual-fuel heat pump combines an electric heat pump with a gas furnace, providing both heating and cooling. This system is energy-efficient since it relies on the heat pump for milder temperatures and the gas furnace during extreme cold, optimizing comfort and reducing energy costs.

What are some common drawbacks of opting for a packaged air conditioner?

The common drawbacks of choosing a packaged air conditioner include potential exposure to weather elements, causing wear and tear. It may also be more challenging to service roof-mounted units and there can be limitations on size or capacity due to the all-in-one design.

What is the expected lifespan of a packaged HVAC system, and how does it compare to other types?

A packaged HVAC system typically has a lifespan of 15 to 20 years, which is comparable to split systems. The overall longevity hinges on factors like maintenance regularity, usage intensity, and the environment where it’s installed. Regular maintenance can help achieve or extend this expected lifespan.